Why Cummins diesel generator overheats during operation

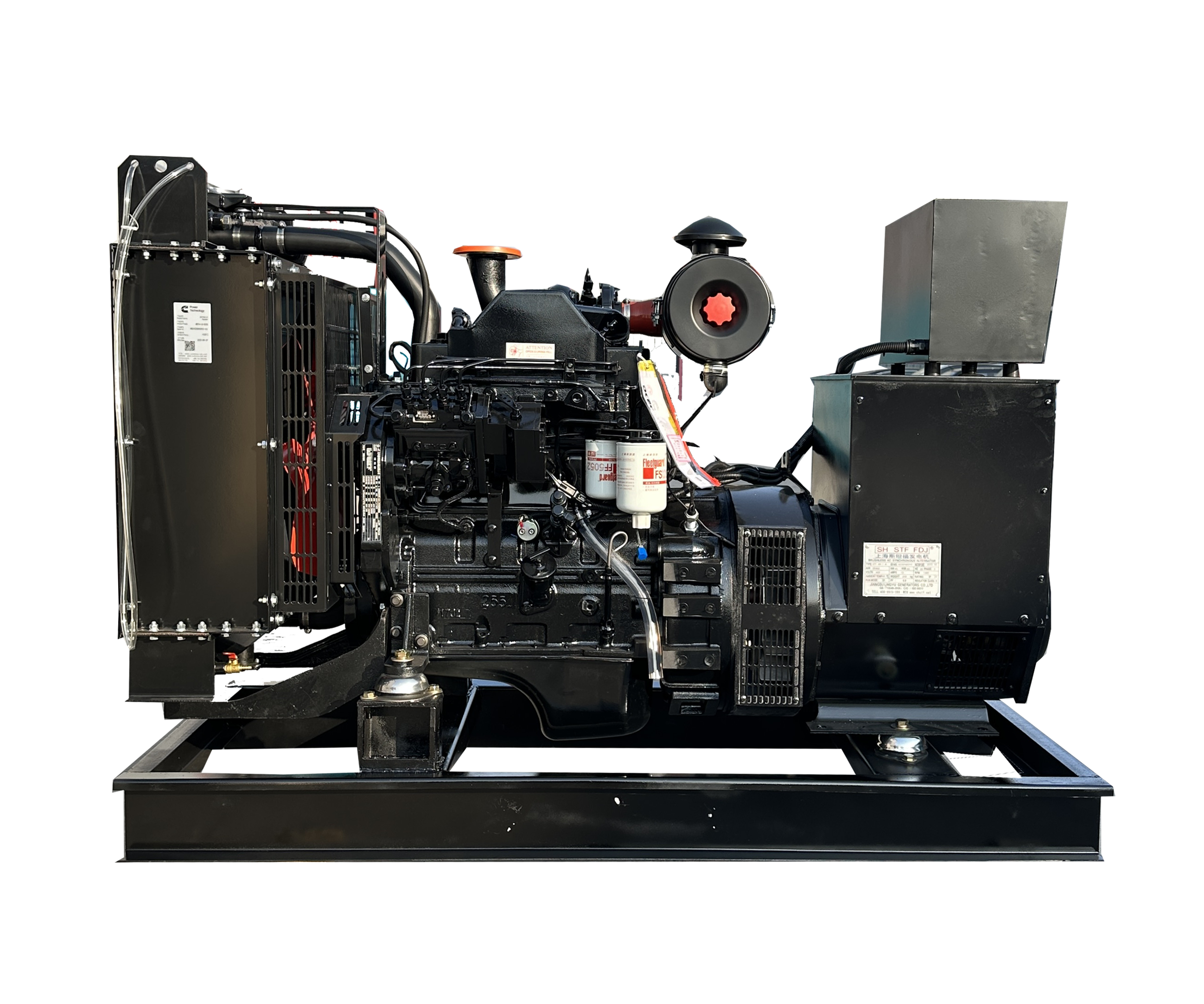

Cummins diesel generator is characterized by stable operation, low noise, low fuel consumption and low operating cost, so it is widely used in mines, ships, ports, factories and other places. Cummins diesel generator will overheat under high load, which is one of the common problems of Cummins diesel generator. Then, the diesel generator manufacturer gives the following explanations:

1、 Abnormal operation

The diesel generator shall be operated according to the specified technical conditions, otherwise the generator will overheat due to abnormalities, including:

- If the load current is too large, the copper loss of stator winding will increase.

- If the frequency is too low, it will reduce the speed of the cooling fan and affect the cooling of the generator;

- If the power factor is too low, the excitation current of the rotor will be increased, thus heating the rotor.

Solution: Check whether the display of the monitoring equipment is normal. In case of abnormality, necessary adjustment and handling must be carried out.

2、 Unbalanced current - The difference between three-phase currents is not allowed to exceed 10% of the rated current. If it exceeds 10%, it indicates that the three-phase load current of the diesel generator is unbalanced, which is the main reason for overheating of single-phase windings.

- The unbalanced three-phase current generates a negative sequence magnetic field, which leads to increased losses and heating of the pole windings and rings.

Solution: The three-phase load must be adjusted to make each phase current as balanced as possible.

3、 Blocking problem - The air duct is blocked by dust. Poor ventilation makes it difficult for the diesel generator to dissipate heat. The dust and grease in the air duct shall be removed to make the air duct unobstructed.

- Exhaust pipe is blocked. When the exhaust pipe is blocked, the exhaust cannot be discharged smoothly when the diesel generator set is running, and part of the exhaust remains in the cylinder. If there is more exhaust gas in the cylinder in the next intake stroke, the fresh oil air mixture will not enter completely. When the spark plug is ignited, the flame propagation and combustion speed are slow and the combustion time is long, which occurs after combustion.

- The oil filter screen is blocked. The oil filter is installed at the inlet of the oil pan oil suction unit to remove air bubbles and prevent large impurities from entering the oil pump.

Solution: If the oil filter is blocked, the lubricant supply of the diesel generator set will stop, the friction part of the generator set will cause dry friction, and the generator set will overheat.

4、 Running bearing problems - Bearing lubrication is usually 1/2~1/3 of the bearing cavity (upper limit of low speed and lower limit of high speed), and should not exceed 70% of the bearing cavity

- The bearing is worn. Serious bearing wear will cause friction between stator and rotor, resulting in local overheating of stator and rotor.

Solution: Check whether there is friction between the stator and rotor, and whether there is noise in the bearing. If there is, stop the machine immediately for maintenance or replace the bearing.

5、 Cooling fault - The cooler is blocked due to high inlet air temperature or high inlet water temperature.

Solution: In order to avoid blockage of cooler, the temperature of air inlet or water inlet must be reduced. - Radiator or pipe leaks. The radiator or pipe leaks, and the water tank of the diesel generator has limited water storage, resulting in overheating of the generator set.

Hi, this is a comment.

To get started with moderating, editing, and deleting comments, please visit the Comments screen in the dashboard.

Commenter avatars come from Gravatar.