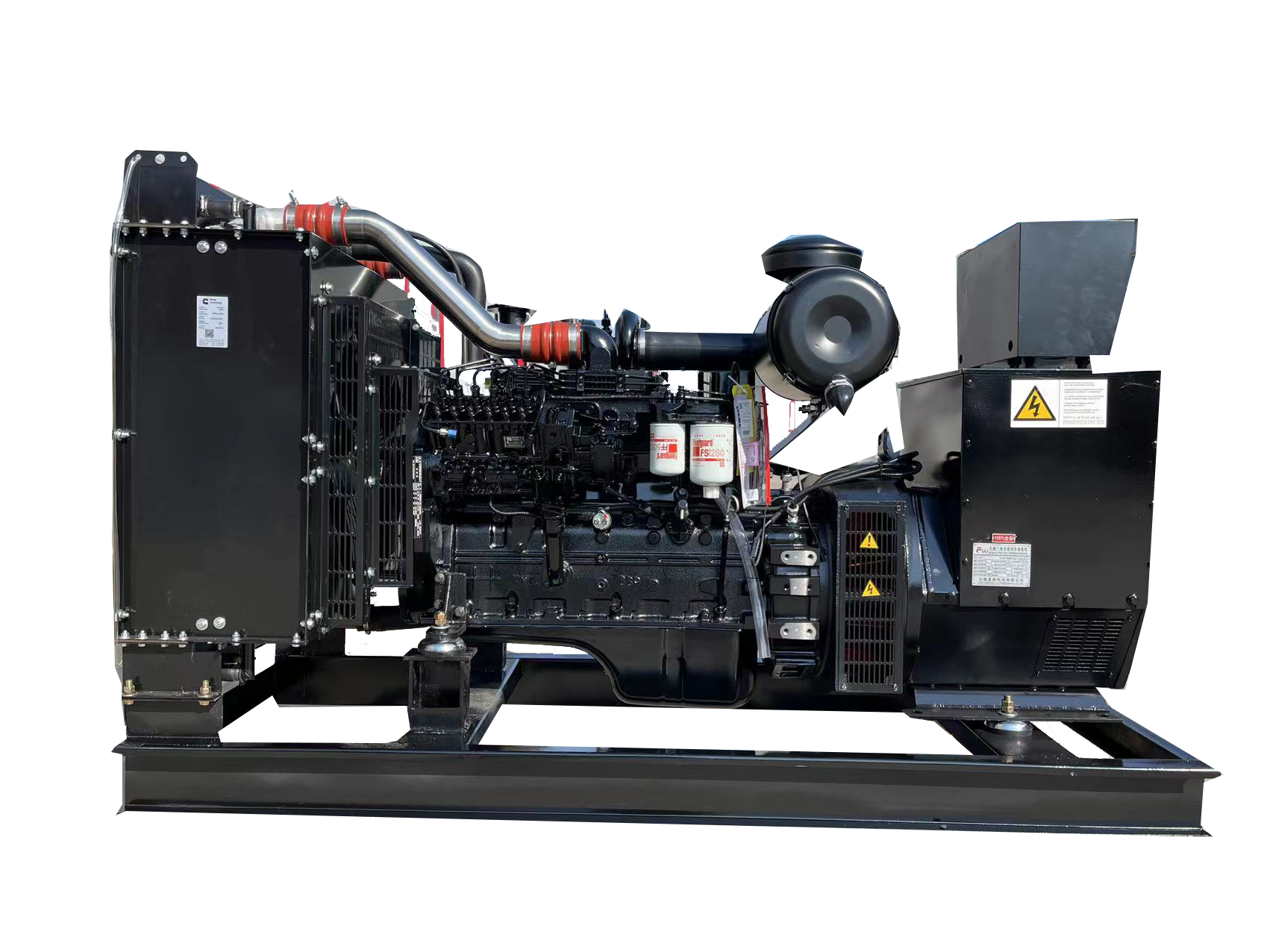

How to avoid the vibration of Cummins generator?

In addition to the vibration caused by its own reasons, the vibration and instability of the surrounding environment will also affect the equipment. In the process of maintenance of Cummins generators, users should adopt strategies to prevent damage to Cummins generators. There are many reasons for damage, and shaking is a cause that cannot be ignored

During the maintenance of Cummins generator, if it is necessary to move the Cummins generator, it is recommended to use a shock absorber. The shock absorber instrument needs to be fastened to the concrete foundation with expansion bolts. The operator places the Cummins generator on a flat and stable foundation through the shock absorber according to the equipment holes on the chassis of Cummins generator.

This can effectively reduce the vibration and impact on the building caused by the operation of Cummins generator. In addition to Cummins generator and its foundation through the shock absorber device, other parts of Cummins generator should also be connected to the outside through flexible connection.

For example, the exhaust pipe is connected with corrugated damping pipe, and the smoke exhaust duct, fuel inlet pipe, oil return pipe, distribution cable, etc. are also connected through flexible connection, so as to minimize the vibration of the surrounding objects caused by the operation of Cummins generator.

In addition, the parts inside the equipment also need to be shockproof. The simplest strategy is lubrication and maintenance. Check the friction between the parts, and find out the shortcomings of the equipment itself for timely inspection. Only in this way can wear be effectively reduced. The safety and application life of Cummins generators can also be guaranteed.